What are the Advantages of a Carpet Making Machine Compared with Traditional Handmade Methods?

What are the Advantages of a Carpet Making Machine Compared with Traditional Handmade Methods?

Blog Article

In the realm of carpet production, the choice between using a Carpet Making machine and traditional handmade methods can significantly impact the success of your business. Carpet making machines have revolutionized the industry, offering numerous benefits that traditional methods simply can't match. Let's explore the key advantages in detail.

1. Unprecedented Production Speed

Traditional handmade carpet production is a tedious and time-consuming process. Experienced craftsmen carefully make each knot, weave, and cut each carpet by hand. Even the most simplest handmade carpet might take weeks and in some cases even months to reach the completion stage. As a result of this high slowness, the amount of produced goods becomes very low and it becomes very hard to meet large - scale orders in a timely manner.

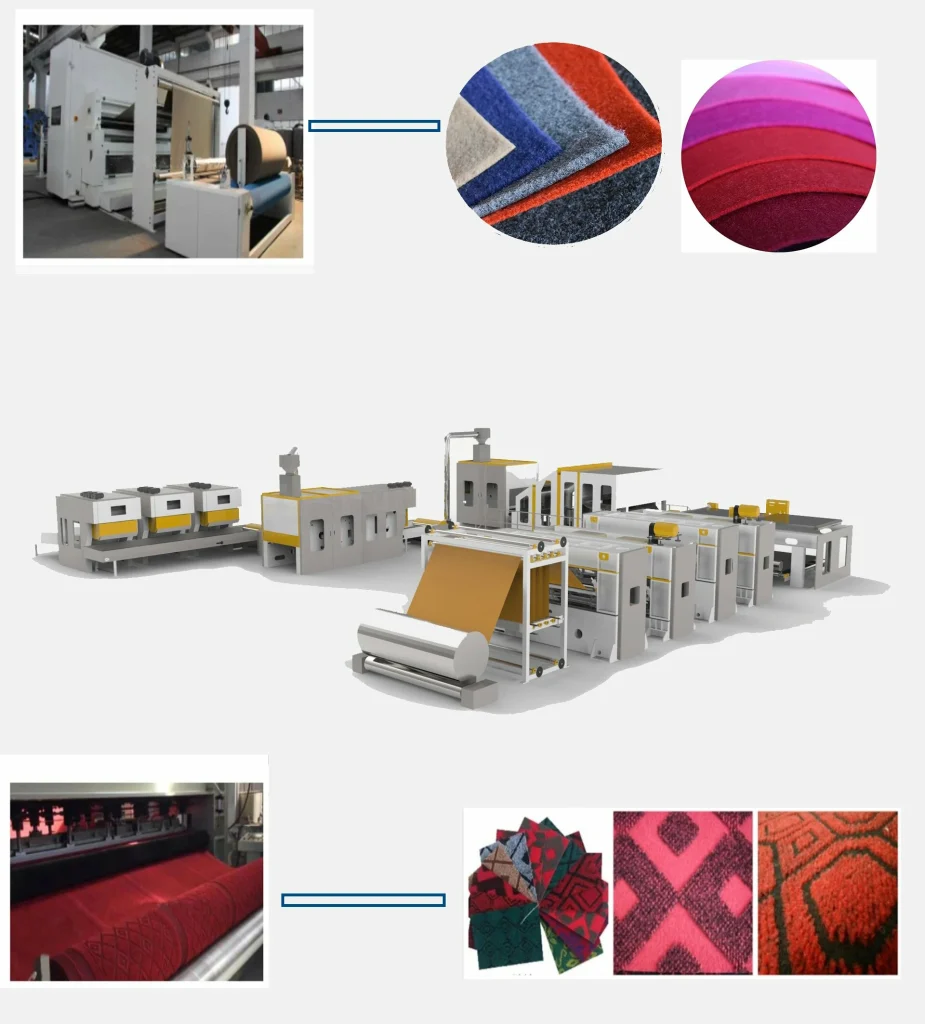

Carpet making machines are built for speed production. Today's carpet production lines, which are high-tech, are capable of producing numerous carpets in a short time. Automatic looms and needle punching nonwoven making machines in machine-carpet production can fully finish a rug.The strength of machine-carpet production lies in satisfying the end-user requirements. This high production speed enables manufacturers to process large orders, be responsive to market changes, and grasp the dominant market position in the industry.

2. Significant Cost Reduction

Expenses have always been a top priority for every business, and the capital machinery used in carpet making process is a window of significant cost-effective opportunities.

Workforce Expenses

Rug weaving, which is done by hand, requires a lot of masterly craftsmen. It is a very expensive solution to employ, train, and pay these workers. But a machine saves time by automating a large number of processes, thus labor is less needed. Consequently, the overhead is also lower as it requires fewer workers who are responsible for operating as well as monitoring the machines.

Material Loss

Machinery used for carpet making is designed quite accurately. They can perform the exact procedures such as cutting, shaping, and assembling with almost zero waste. Computer-aided systems guarantee a steady and high usage of all the yarn and fabric. On the contrary, the human factor and less precise methods of cutting and shaping in the traditional hand-making method led to more material waste.

Energy Efficiency

A lot of carpet making machines in use today have got eco-friendly features. Such energy-saving equipment consumes less power that is while high-quality output is still maintained by these machines. This not only cuts production costs but also turns the production process more eco-friendly.

3. Consistent Quality Assurance

Quality is the most important thing in the carpet industry, and the machines used in carpet manufacturing provide a standard of quality that is very hard to be achieved by the older, traditional handmade method.

A unique aspect of handmade carpets is that the quality of the carpets can vary a lot, even when made by the same person. Inconsistent tension, the amount of time spent on the carpet, and the type of tools used may all contribute to the different variations. The variations in craftsmanship may cause changes in the feel, life, and look of the carpet.

During the production of carpets, the machines, for their part, work with a standard process and components and produce the products in a stable manner. The use of new technologies guarantees that every single carpet has been made at a given level of quality. Whether it is the density of the pile, the strength of the weave, or the accuracy of the pattern, machines can produce exactly the same quality standards every time.

4. Versatility in Design and Application

Scope of Design

Manufacturers benefit greatly from the use of computer-aided design (CAD) software, the integrated capabilites of which make it possible to express intricate and diverse patterns readily. These machines can easily change between different designs, enabling quick adjustments to changing market trends. Meanwhile, new designs in handmade carpets, in general, require artisans to go through a long and arduous process of learning and implementing new skills to create them.

Application Diversity

Carpet making machines allow people to produce carpets for a huge variety of applications. They are applied in the automotive industry to make car floor mats and interior carpets, the construction industry to manufacture floor coverings for business and residential buildings, and the hospitality sector to design carpets for hotels and restaurants. Moreover, they can also produce carpets with unique properties like sound absorption and flame resistance, thanks to integrated machines.

Conclusion

Carpet making machines offer clear benefits in efficiency, cost - effectiveness, quality, and versatility. For reliable and high - performing options, AoLong Non-w

Report this page